From the day of establishment in 1968, we have been developing manufacturing technology and system through design and manufacture of various industrial computer control equipment to turn every customer’s “idea and passion” into products for almost half a century. We serve our customers with aggressive effort in advanced technology to be true to Japan quality, and passionate manufacturing which is a mixture of “thought put into the product” and “friendliness to user and society”.

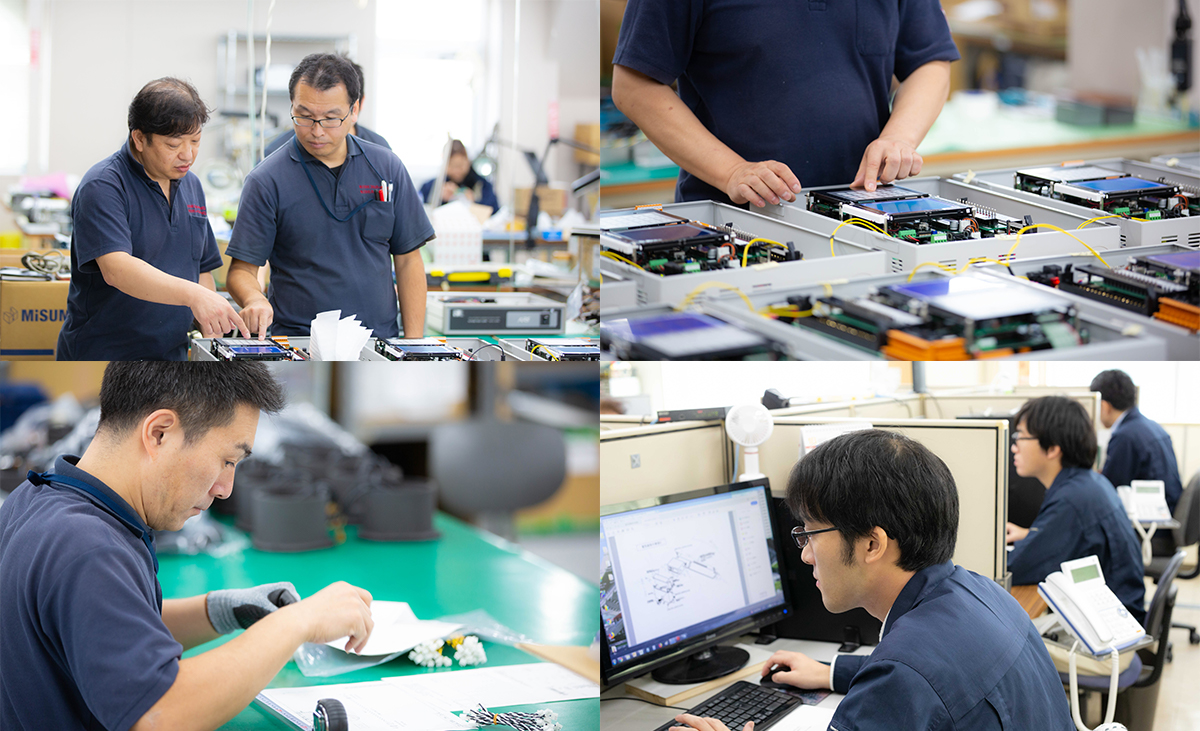

From procurement of a small part to assemblies and final products, we offer solutions for design, process, assembly to fit various customer needs to realize customer’s “idea”.

With extensive development experience and integrated system to grasp the whole process, we participate in planning and design and consistently support customer in procurement and manufacture to turn customer’s idea into product.

As professionals, we contribute customers by “fabricating” a high quality product based on customer’s concept. We also provide you with consultations on mass production or optimization of draft drawing before manufacture.

We respond to customers’ requests taking advantage of our system and strengths we have developed, as well as “manufacturing with passion” faithful to customer’s thought and strong “partnership”.

We have the vertical integrated production system from design,

parts procurement, process to assembly. The advantages of this system are:

Our integrated production system maintains high and stable quality by strict in-house quality check system for the whole process.

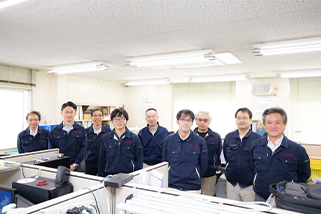

Each process is assigned to corresponding division, and sufficient communication and information sharing between divisions facilitate production process and also contribute to improved quality.

We quickly and smoothly respond to minor design modification and specification change requests from customers through integrated in-house process.

Our streamlined production system accept small scale production at reasonable and fair prices.

We offer design, parts procurement, manufacturing workpiece and substrate, wiring, assembly, modification, adjustment of various units, mechatronics apparatus, control panel through integrated system.

We strictly check quality by thorough in-house quality check system in our factory consistently. Gained quality management system (ISO9001) certification

Having a high level of processing technology unique to Ota Ward in Tokyo,

known as an industrial area, we are capable of design and development of all relevant software / hardware.

In the industrial area of Ota Ward, many small factories with unrivaled metal processing technologies gather and form a unique culture. 80% of them are very small factories with less than 10 employees, but they are known for cooperativeness and taking advantage of the synergies of their professional technologies, while sophisticating own technologies.

Collaborations with Ota Ward and us

In addition to delving into processing technology as stated, we also meet volume demand in own plant for precise assembling and sheet metal working in Harvest Japan in Ibaraki Prefecture. We can meet customer need for mass production as well as advanced technology.

About Fullheart Japan and Harvest Japan

We have developed and produced various products in different industries like space development, medical care, and household. Our engineers have accumulated wide knowledge across categories through broad experiences in development and now support the quality of our technology.

We make efforts to improve techniques within the company like technique sharing meetings led by experienced engineers and meetings to review newly developed products.